Wafer cutting process

- Home

- /

- Blade Dicing Process

Blade Dicing Process

The Blade Dicing process utilizes a diamond blade to cut along the scribe lines of the wafer through a "simultaneous grinding and digging" technique. This method separates the entire wafer into individual die, ensuring consistent die dimensions and providing a stable foundation for subsequent packaging and testing processes.

What ProPowertek can do for you?

ProPowertek employs high-precision, fully automatic dual-spindle dicing machines from the internationally renowned DISCO Corporation. Using different dicing blades on spindles Z1 and Z2 (Blade Dicing method), we efficiently and reliably dice wafers—mounted on dicing tape and metal frames—into individual die.

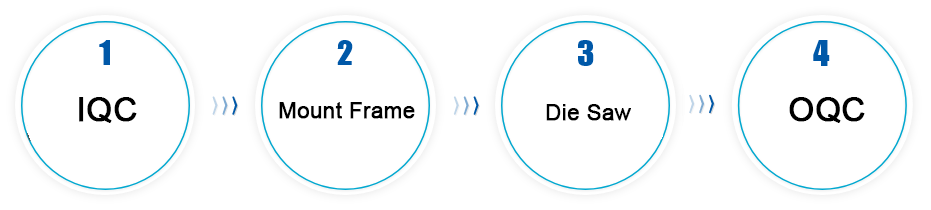

Wafer Dicing Process

機台會有固定時間,週期性的進行機台穩定度的檢測,利用控片分別進行各反應腔(Chamber)的測試,在ICP反應腔中會進行蝕刻率測試,在鋁(Al)、鈦(Ti)、鎳釩(NiV)、銀(Ag)則會分別進行沈積率及均勻性的預測試,確定了機台狀況一如往常的平穩後,產品會依照排程開始進入生產,客戶的晶圓在完成入站檢驗 (IQC) 後,客戶可要求進行沈積前DHF清洗或是直接進入濺鍍機,按照客戶指示之種類及厚度及ICP條件,進行金屬沈積 (Sputtering Deposition),完成金屬沈積後,可依客戶需求進行沈積後之氮氣退火,或是直接進行出站檢驗 (OQC)。

The Superiority of ProPowertek

▶ By integrating Taiko Grinding, Taiko Ring Removal, and Die Saw processes—all using a full suite of fully automated DISCO equipment—ProPowertek provides a precise and reliable turnkey solution.

▶ Equipped with fully automatic dual-spindle dicing machines, we utilize different dicing blades on Z1 and Z2 spindles to efficiently dice wafers into individual dies.

▶ ProPowertek is equipped with AOI (Automatic Optical Inspection) systems to provide post-dicing die inspection services. When combined with CP (chip probing) wafer testing, we generate a complete wafer map to assist in good die selection for downstream packaging.

▶ Our engineering team has a diverse background, including experts from front-end wafer foundries, wafer thinning specialists, and back-end packaging houses. This allows us to offer deep knowledge in front-, mid-, and back-end process integration and analysis, enabling us to support rapid development, problem-solving, and stable mass production for our customers.

Case Sharing

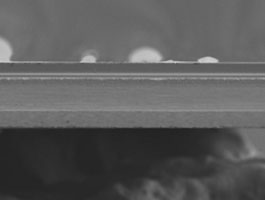

Cross-sectional SEM Image After Die Saw

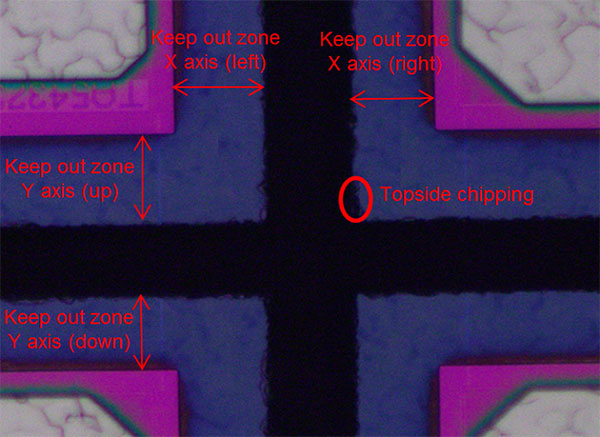

Quality Inspection After Die Saw